CASE HISTORY

Steady State Vs Transient Drilling: Protecting Against Unwanted Downtime

WellWatch, Protecting Against Unwanted Downtime

What does Steady State mean?

A steady state flow process requires conditions at all points in an apparatus or system remain constant as time changes. There must be no accumulation of mass or energy

In the case of drilling operations, accumulation of mass would be represented by “excess cuttings”.

-

- Hole cleaning at optimal cleaning rates governed by cutting carrying indices is imperative.

What is Transient or Non-Steady State?

Unsteady-State: in unsteady-state processes, mass and energy in the system are changing with time (not constant).

-

- A condition not conducive to processes like automation

- Steady State processes are always better, more reliable and efficient.

- Drilling is no different

Case History – The New DrillSage ROP Moving Average: Contrast Wells

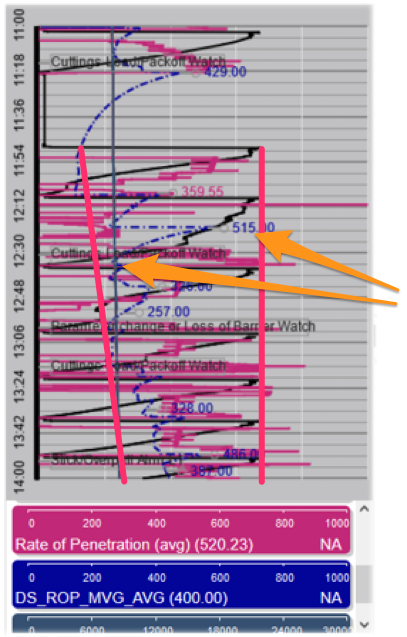

Well 1: Erratic and Transient Drilling Practice: Note “Watches”

Note Excessive Bandwidth:

-

- Creates potential hazards due to “mass” or cuttings loading

- Exacerbates motor and downhole tool wear

6000’ Lateral:

Drilling ahead average ROP: 180

FPH. Total hours: 33.33

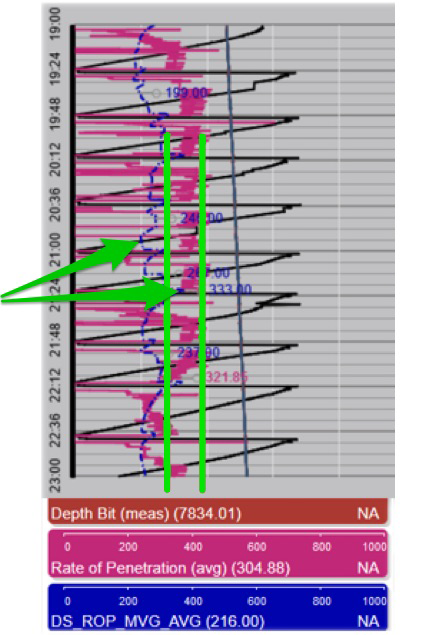

Well 2: Steady State

Note Bandwidth Improvement:

-

- Reliable and efficient hole cleaning

- Better average ROP even though ultra high rates are not forced

6000’ Lateral:

Drilling ahead average ROP: 164

FPH. Total hours: 36.59