CASE HISTORY

Deepwater DrillSage Performance Case History: Management Comments

“We started from a position of skepticism with the rig team. No one was sure we needed this or what it would do for us. As we used the system, we progressed to see it as reliable, and we could use it with confidence”

“This is the next best thing to MPD”

“All of the watches and alarms that are forwarded have changes that we want to see. We are all very senior, sometimes we expect to see the things that are called out. They’re all valid“

“You’re giving us ammo to fight against this bad [redacted] equipment that we were forced to work with by procurement.”

“Sr Mgt logged into the XXX system one time and found the XXX system too clumsy, too cumbersome to use compared to the DrillSage system and never logged into the XXX system again for the multiple months of the well operations.”

“We plan to use DrillSage again on our next deepwater well later this year.”

“Corrective actions as a result of “watches” and nonfictions eliminated alarm saturation”

Relevant Watches and Alarms:

By recognizing situational awareness of evolving adverse conditions, the team made necessary corrective actions:

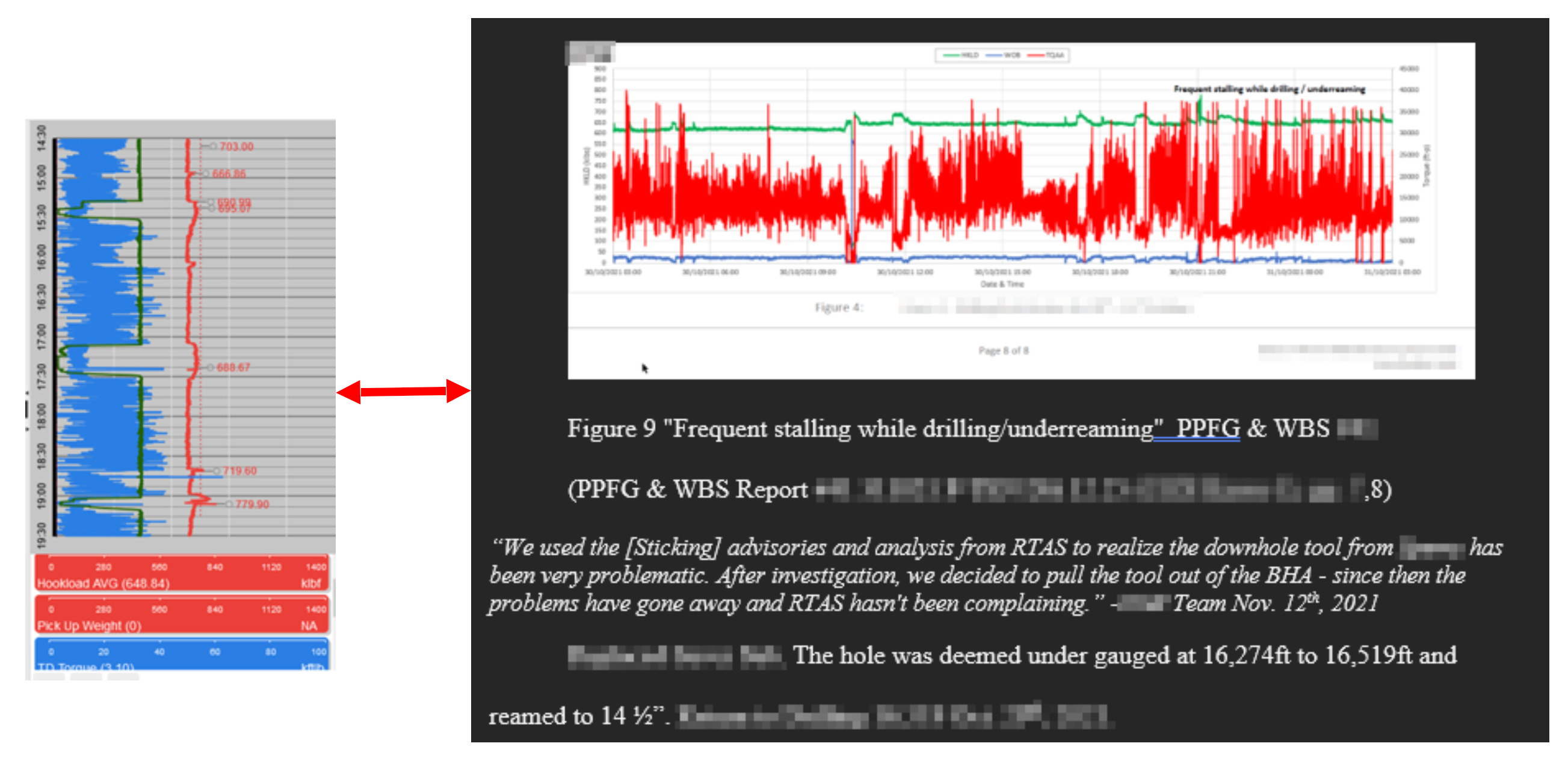

- Helped the drill team recognize “sticking” causation and eliminate by:

- Overpull fingerprinting: Real time torque/drag modeling, as an algorithm

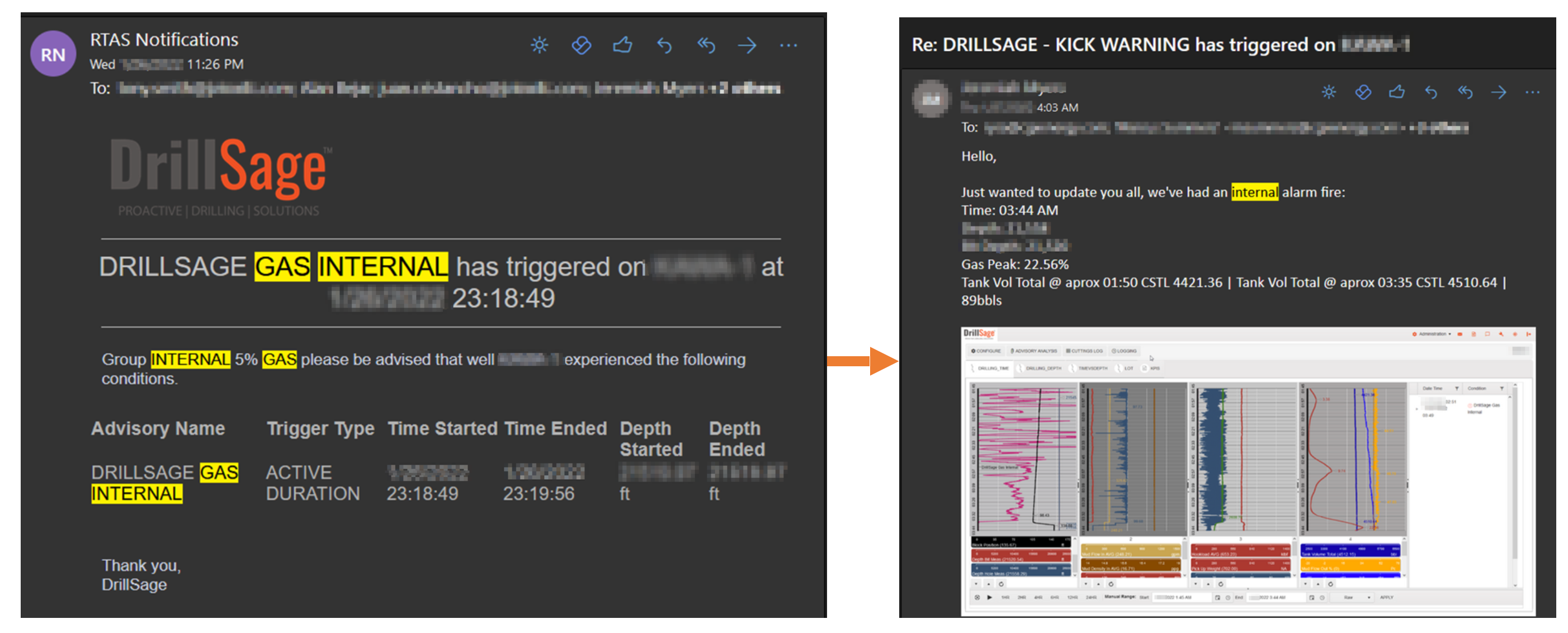

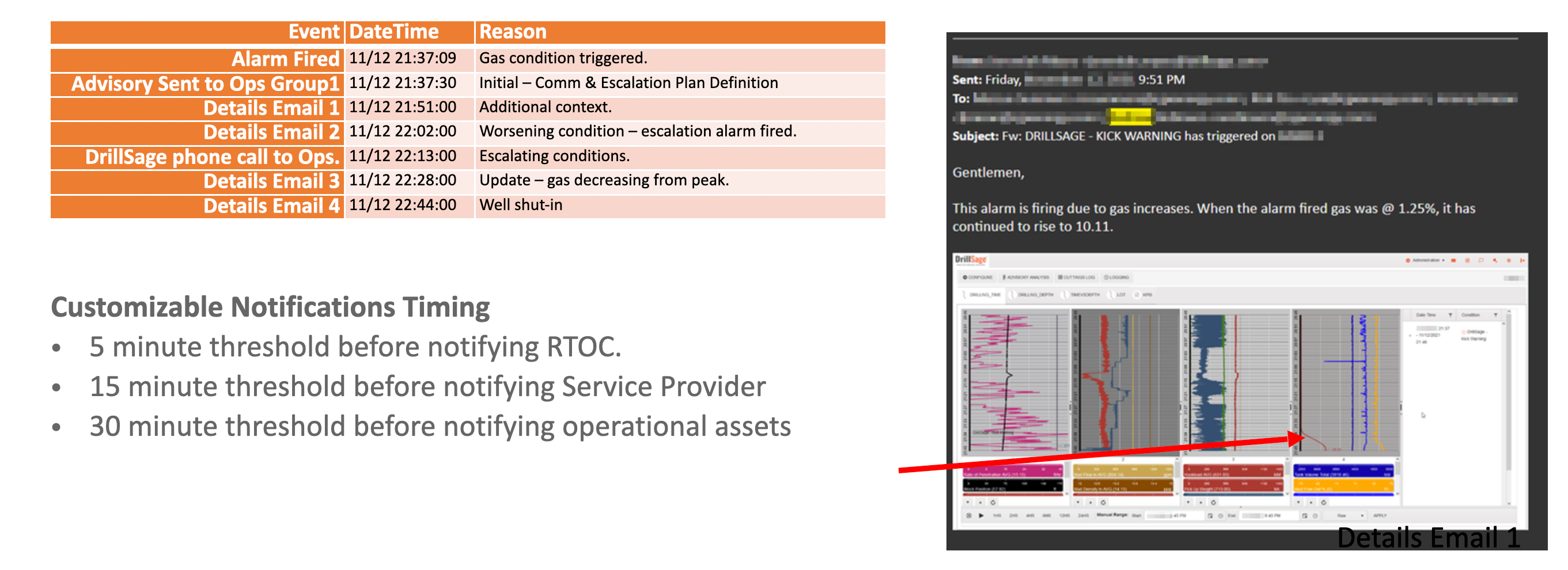

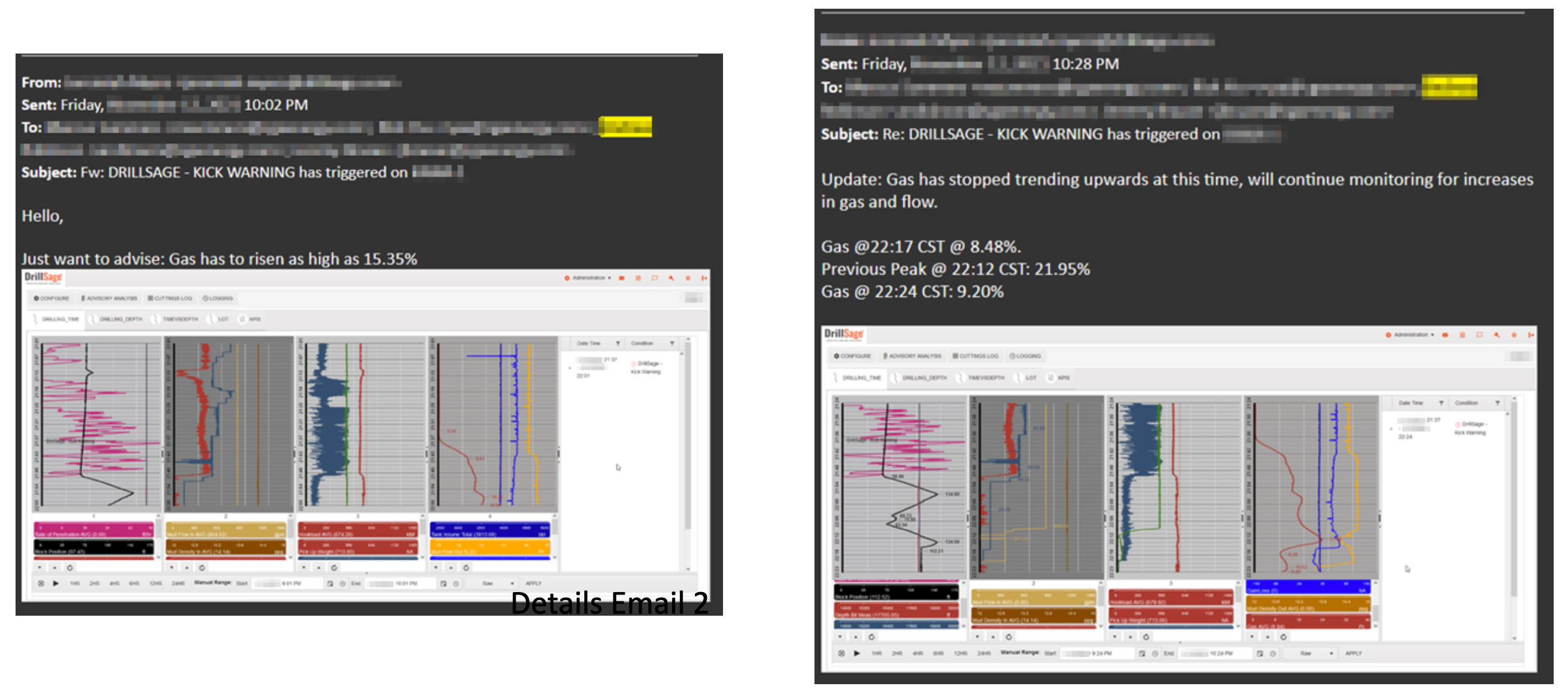

- Kick recognition elevated to critical personnel on a just-in-time basis

Key Functionalities:

- The system provided predictive Watches and alarming notifications for safety-critical operations.

- Customized Notifications were elevated by group

- Notifications are sent via Email, Text, System, etc., to escalation groups based on predefined conditions.

- Watches and Alarms are generated through the analysis of data from external sources and have different severity levels.